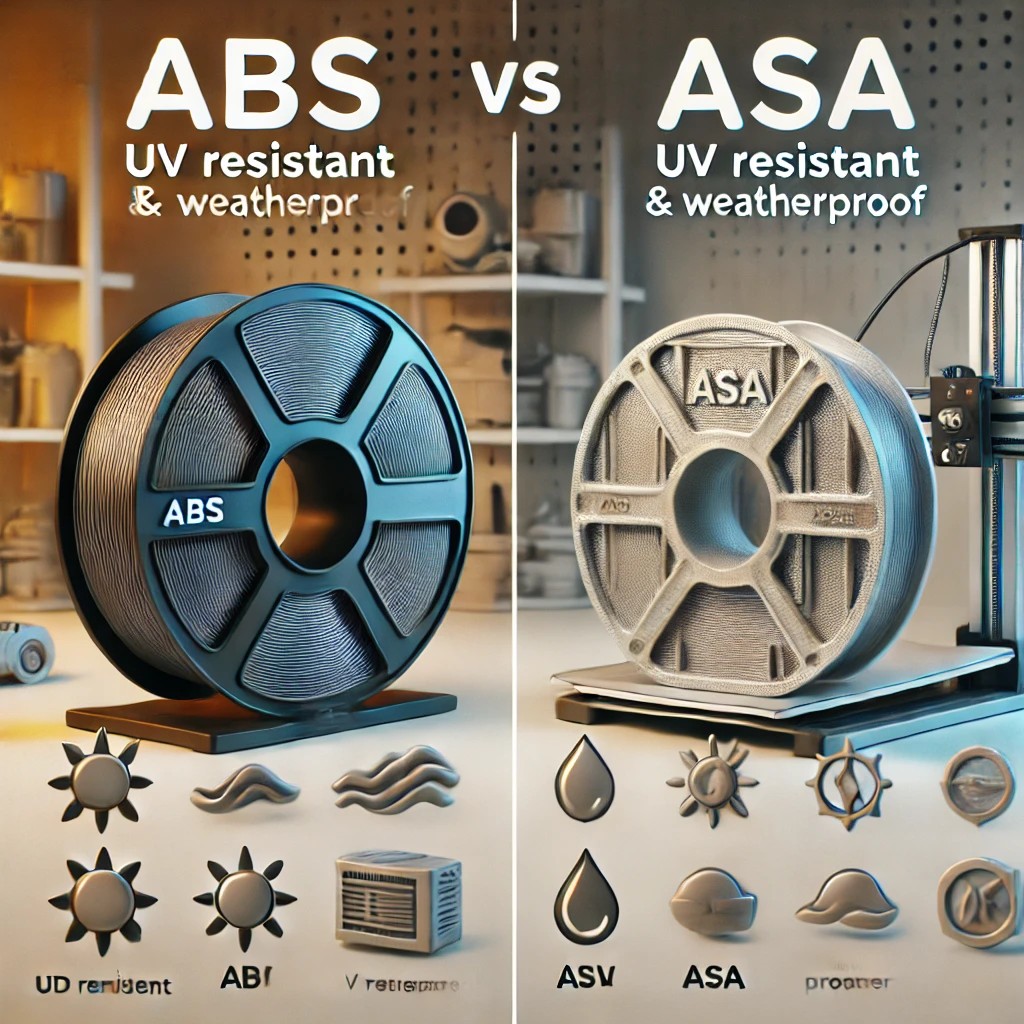

When it comes to 3D printing and manufacturing, choosing the right material is crucial to the success of your project. Two popular thermoplastics often considered for such projects are ABS (Acrylonitrile Butadiene Styrene) and ASA (Acrylonitrile Styrene Acrylate). Both materials share similar properties, but each has its unique strengths and weaknesses that make them suitable for different applications. In this article, we’ll dive deep into the key differences between ABS and ASA to help you decide which material is best suited for your needs.

What is ABS?

ABS (Acrylonitrile Butadiene Styrene) is a widely used thermoplastic known for its strength, durability, and ease of processing. It is a popular material in both 3D printing and traditional manufacturing due to its balanced properties.

Key Characteristics of ABS:

- Strength and Durability: ABS is known for its high impact resistance and toughness, making it ideal for products that need to withstand mechanical stress.

- Ease of Processing: ABS is relatively easy to process, making it a favorite for injection molding and 3D printing. It has good flow properties and can be easily machined or post-processed.

- Cost-Effective: ABS is one of the more affordable engineering thermoplastics, making it a cost-effective choice for both prototypes and end-use parts.

- Heat Resistance: ABS has decent thermal stability, with a heat deflection temperature (HDT) typically around 100°C, allowing it to withstand moderate temperatures.

- Surface Finish: ABS can be sanded, painted, and polished, offering flexibility in finishing options.

Common Applications of ABS:

- Automotive parts (e.g., dashboards, trim components)

- Consumer goods (e.g., toys like LEGO bricks, electronic housings)

- Industrial equipment

- Prototyping and functional parts

What is ASA?

ASA (Acrylonitrile Styrene Acrylate) is a thermoplastic that shares many similarities with ABS but offers enhanced weatherability and UV resistance. It was developed as an alternative to ABS for outdoor applications.

Key Characteristics of ASA:

- UV Resistance: ASA is highly resistant to ultraviolet (UV) radiation, making it ideal for outdoor applications where exposure to sunlight is a concern. Unlike ABS, ASA does not degrade or lose color when exposed to UV light.

- Weather Resistance: ASA offers superior resistance to weathering factors such as rain, wind, and temperature fluctuations. It retains its mechanical properties and appearance even in harsh outdoor environments.

- Chemical Resistance: ASA is more resistant to certain chemicals, including acids and bases, compared to ABS, making it suitable for more demanding environments.

- Mechanical Properties: While slightly less impact-resistant than ABS, ASA still offers good toughness and strength, making it suitable for a wide range of applications.

- Dimensional Stability: ASA has better dimensional stability than ABS, reducing the risk of warping during the printing process.

Common Applications of ASA:

- Outdoor furniture and fixtures

- Automotive exterior parts (e.g., mirror housings, trims)

- Sports and recreational equipment

- Electrical housings exposed to outdoor conditions

- Signage and outdoor displays

Comparing ABS and ASA

Let’s break down the comparison of ABS and ASA based on several key factors:

- UV and Weather Resistance

- ABS: Susceptible to UV degradation and discoloration when exposed to sunlight over time. Not ideal for prolonged outdoor use.

- ASA: Highly resistant to UV rays and environmental weathering, making it perfect for outdoor applications.

- Mechanical Strength and Impact Resistance

- ABS: Slightly higher impact resistance, making it better suited for applications where mechanical stress is a concern.

- ASA: Slightly lower impact resistance compared to ABS but still offers robust performance for most applications.

- Heat Resistance

- ABS: Similar heat resistance to ASA with a heat deflection temperature around 100°C.

- ASA: Comparable heat resistance to ABS, suitable for both indoor and outdoor applications with moderate heat exposure.

- Chemical Resistance

- ABS: Resistant to most chemicals, but can be affected by prolonged exposure to certain solvents and acids.

- ASA: Offers better chemical resistance than ABS, particularly against acids, bases, and other harsh chemicals.

- Surface Finish and Aesthetics

- ABS: Can be easily sanded, polished, and painted, making it versatile for cosmetic applications.

- ASA: Provides a similar surface finish to ABS but with added UV resistance, ensuring that colors remain vibrant and do not fade when exposed to sunlight.

- Ease of Printing

- ABS: Prone to warping during 3D printing, especially with larger parts. Requires a heated bed and controlled environment to minimize warping.

- ASA: Less prone to warping due to better dimensional stability, making it easier to print, especially for larger objects.

- Cost

- ABS: Generally more affordable than ASA, making it a cost-effective choice for many applications.

- ASA: Slightly more expensive than ABS due to its enhanced weatherability and UV resistance properties.

Which Material Should You Choose?

The choice between ABS and ASA largely depends on the specific requirements of your project:

- Choose ABS if:

- You need a strong, durable material for indoor use.

- Cost is a significant factor in your decision.

- Your project involves parts that require post-processing, such as sanding, painting, or polishing.

- Choose ASA if:

- Your project involves outdoor applications where UV and weather resistance are critical.

- You need a material that can withstand exposure to harsh chemicals.

- You require a material with excellent dimensional stability and ease of printing.

Conclusion

Both ABS and ASA are excellent thermoplastics, each with its own strengths. ABS is a versatile, cost-effective option suitable for a wide range of indoor applications, while ASA is the go-to material for outdoor projects that demand superior UV and weather resistance. By understanding the differences between these two materials, you can make an informed decision that ensures the success and longevity of your 3D printing projects.

Sources

https://all3dp.com/2/asa-vs-abs-differences

https://www.wevolver.com/article/asa-vs-abs

https://europlas.com.vn/en-US/blog-1/abs-vs-asa-what-are-the-differences

Discover more from PrintCraft.gr

Subscribe to get the latest posts sent to your email.

Thank you for your help and this post. It’s been great.