Introduction

Infill patterns are a crucial aspect of 3D printing that greatly influence the strength, weight, flexibility, and print time of your final product. Understanding the different types of infill patterns available and their best applications can help you optimize your prints for specific needs. In this article, we’ll explore and compare the most common infill patterns, discussing their pros, cons, and ideal use cases.

1. Rectilinear Infill

Rectilinear is one of the most basic infill patterns available in most 3D printing slicers. It consists of straight, parallel lines that alternate direction with each layer, creating a grid-like structure.

Pros:

- Simple and Fast: Due to its straightforward design, rectilinear infill is quick to print, making it ideal for prototypes and non-structural parts.

- Consistent Strength: Provides decent strength in both the X and Y axes.

Cons:

- Limited Strength: While it offers balanced strength, it’s not the best for high-load applications.

- Wasteful: Can be less material-efficient compared to more advanced infill patterns.

Best For: Basic prototypes, low-stress parts, and rapid printing.

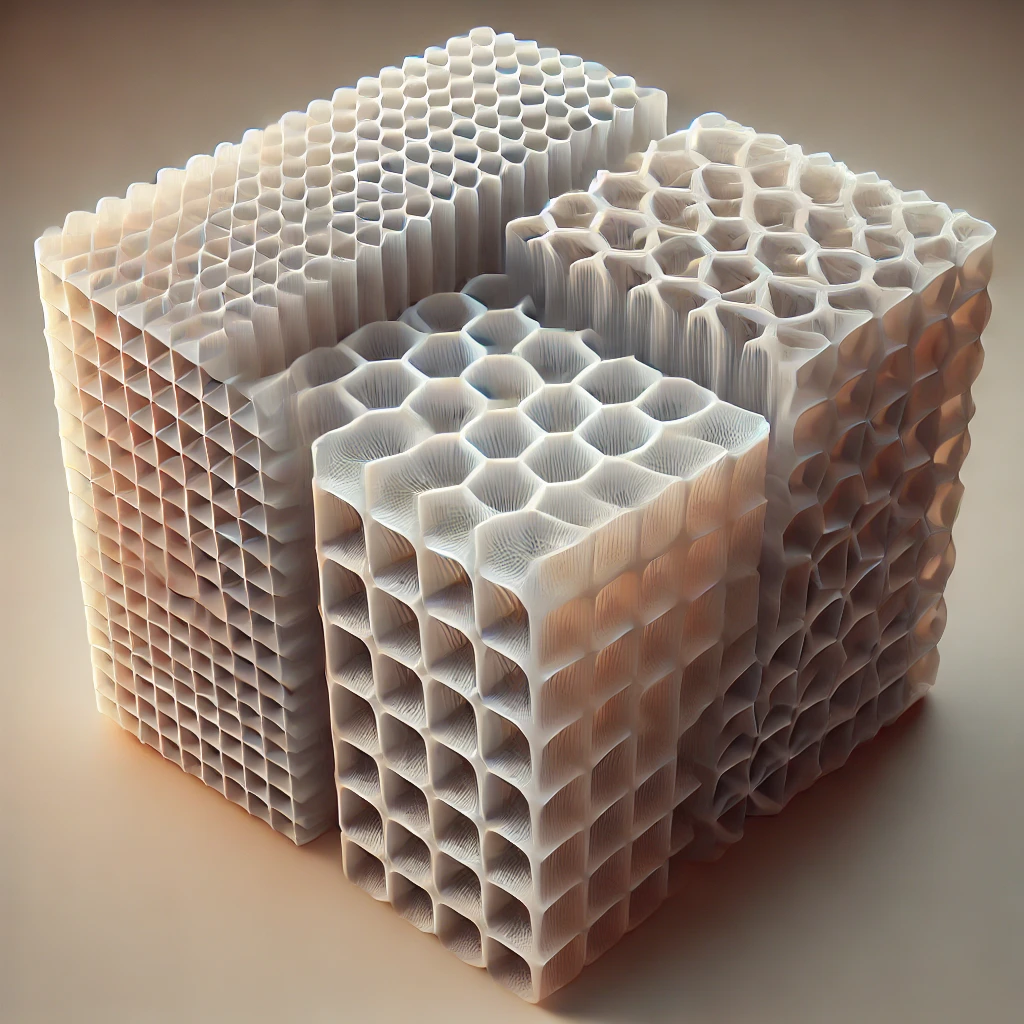

2. Honeycomb Infill

Honeycomb infill mimics the hexagonal structure found in natural honeycombs, offering an excellent balance of strength and material efficiency.

Pros:

- High Strength-to-Weight Ratio: Honeycomb structures are renowned for their strength, making this infill pattern ideal for parts that need to be strong yet lightweight.

- Efficient Material Use: The hexagonal cells reduce material usage while maintaining strength.

Cons:

- Slower Print Times: The complexity of the pattern means it takes longer to print compared to simpler infills like rectilinear.

- Difficult Cooling: The dense pattern can lead to challenges with cooling, potentially affecting print quality.

Best For: Structural parts, lightweight yet strong components, and applications where strength and weight are critical.

3. Triangular Infill

Triangular infill, also known as grid or tri-hexagonal, uses a series of interlocking triangles to form a strong lattice structure.

Pros:

- Excellent Strength: The triangular structure provides superior rigidity and is particularly good at handling compressive loads.

- Uniform Strength Distribution: Offers consistent strength across multiple directions, making it ideal for structural parts.

Cons:

- Material Intensive: Due to the solid nature of the pattern, it can consume more material than other options.

- Longer Print Times: The complex geometry results in slower print speeds.

Best For: Parts requiring high strength and rigidity, like mechanical components and load-bearing structures.

4. Gyroid Infill

Gyroid infill is a more advanced pattern, characterized by its continuous, organic structure that smoothly transitions between layers.

Pros:

- High Flexibility and Strength: The continuous nature of the gyroid pattern offers excellent strength and flexibility, making it suitable for both rigid and flexible parts.

- Efficient Cooling: The open structure allows for better airflow, reducing warping and improving overall print quality.

Cons:

- Complexity: The pattern is more complex, requiring more processing power and potentially longer slicing times.

- Material Usage: While it offers great strength, it can use more material than simpler infills.

Best For: Flexible parts, aerospace components, and applications requiring a balance of strength and flexibility.

5. Cubic Infill

Cubic infill consists of a 3D grid of small cubes stacked in a repeating pattern, offering strength in all directions.

Pros:

- Isotropic Strength: Cubic infill provides consistent strength in all three axes (X, Y, and Z), making it ideal for parts that need uniform strength.

- Efficient Use of Material: Offers a good balance between strength and material usage.

Cons:

- Longer Print Times: The 3D nature of the pattern increases print time compared to 2D infills.

- Moderate Flexibility: Not as flexible as gyroid or honeycomb patterns, making it less suitable for flexible prints.

Best For: Structural components, parts requiring balanced strength in all directions, and general-purpose prints.

6. Octet (Tetrahedral) Infill

Octet infill, also known as tetrahedral infill, is a 3D pattern composed of interconnected tetrahedrons, offering a high-strength structure.

Pros:

- Maximum Strength: Provides some of the highest strength among infill patterns, particularly in compression.

- Efficient Material Distribution: The tetrahedral structure offers high strength with relatively low material usage.

Cons:

- Complexity and Print Time: The intricate pattern can significantly increase print time and complexity.

- Overkill for Simple Parts: May be unnecessary for non-structural or simple prints.

Best For: High-strength parts, load-bearing components, and aerospace applications.

7. Concentric Infill

Concentric infill consists of layers of concentric shapes (often circles or squares) that expand from the center of the part outward.

Pros:

- Excellent Surface Finish: Ideal for parts where the outer layers’ appearance is critical, such as in decorative items.

- Good Flexibility: Provides some flexibility, making it suitable for prints that need to bend or flex slightly.

Cons:

- Limited Internal Strength: Not ideal for parts that need internal strength, as the pattern doesn’t provide much structural support.

- Wasteful: Can use more material than necessary for non-aesthetic parts.

Best For: Decorative items, flexible parts, and applications where surface finish is a priority.

Conclusion

Choosing the right infill pattern for your 3D prints depends on the specific requirements of your project. For lightweight but strong parts, honeycomb or gyroid infill might be your best bet. If you need maximum strength, especially in compression, octet or triangular infill will serve you well. For general-purpose printing, cubic or rectilinear infill provides a good balance between print time, strength, and material usage.

By understanding the characteristics of each infill pattern, you can tailor your 3D prints to meet your exact needs, whether you’re prototyping, producing structural components, or creating aesthetically pleasing objects.

Sources

https://help.prusa3d.com/article/infill-patterns_177130

https://all3dp.com/2/cura-infill-patterns-all-you-need-to-know

https://xometry.pro/en-eu/articles/3d-printing-infill/

https://all3dp.com/2/infill-3d-printing-what-it-means-and-how-to-use-it

Discover more from PrintCraft.gr

Subscribe to get the latest posts sent to your email.